Die führende Produktsuite zur PLM-Systemintegration

Sie wollen den Informationsfluss zwischen den Systemen Ihrer PLM-Landschaft besser integrieren? Sie wollen Ihre veraltete PLM-Lösung ohne Informationsverlust modernisieren? Sie arbeiten mit externen Entwicklungspartnern eng in Ihren PLM-Prozessen zusammen?

PROSTEPs Integrationslösung OpenPDM hilft Ihnen dabei Ihre PLM Informationen verlustfrei und zum richtigen Zeitpunkt zwischen den Systemen auszutauschen. OpenPDM bietet Ihnen die Konnektivität zu den Systemen der PLM Welt. Sie profitieren von den erprobten und flexiblen Prozessen und viel Erfahrung unserer Expert*innen zur Realisation Ihrer Integrations- und Migrationsaufgaben.

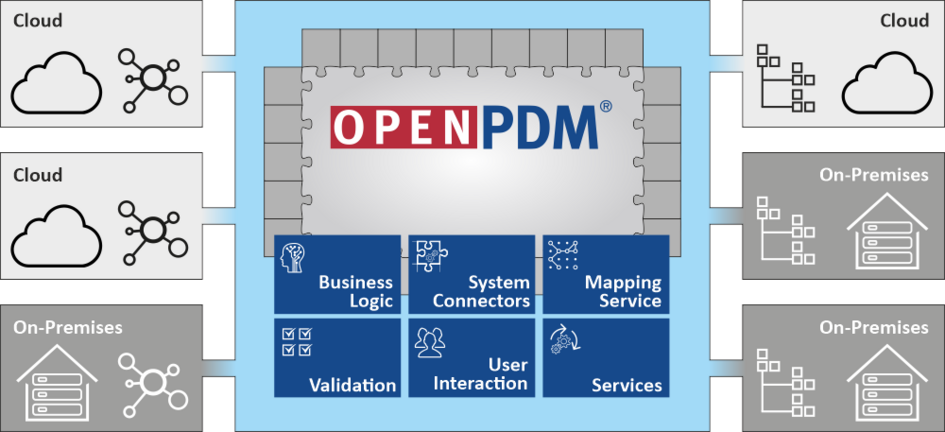

OpenPDM ist auf hybride und heterogene Architekturen vorbereitet. Egal ob altes oder modernes System, On-Premises oder Cloud Architekturen, kleine oder große Datenmengen, wir unterstützen Sie bei der zur Etablierung des durchgängigen Digitalen Fadens.

OpenPDM bietet Ihnen folgende

Leistungsmerkmale und Vorteile:

- Durchgängige PLM-Prozesse

OpenPDM INTEGRATE lässt Ihre PLM-Daten fließen und sorgt über Systemgrenzen hinweg für durchgängige Geschäftsprozesse. So können Sie z. B. den unterschiedlichen Fachbereichen die Daten aus anderen Unternehmensdisziplinen im jeweils verwendeten System zur Verfügung stellen und sind somit immer auf dem aktuellen Stand. - Grenzenlose Skalierbarkeit

Die grenzenlose Skalierbarkeit macht OpenPDM INTEGRATE zur idealen PLM-Integrationsplattform für Unternehmen jeder Art und Größe. Dank der guten Konfigurationsmöglichkeiten lässt sie sich leicht und flexibel an Ihre unternehmensspezifischen Geschäftsprozess anpassen. - Nachvollziehbare Prozesse

Die zentrale Kontrolle über ein intuitiv zu bedienendes Cockpit vereinfacht die Steuerung und Überwachung der Prozesse und macht sie jederzeit nachvollziehbar. Berichte, die auf Knopfdruck ausgegeben werden können, unterstützen die Protokollierung der Prozessabläufe.

- Geringer Administrationsaufwand

Stabilität und Zuverlässigkeit der Software sorgen für einen reibungslosen Betrieb der Anwendungen und reduzieren den Aufwand für die Systemadministration. Die Nutzung der offiziellen Schnittstellen der angebundenen Systeme gewährleistet zudem eine gute Update-Fähigkeit mit geringem Aufwand. - Schneller ROI (Return on Invest)

Im Vergleich zu projektspezifischen Lösungen verfügt OpenPDM INTEGRATE über eine vorinstallierte Business-Logik. Dies ermöglicht eine kurze Implementierungsphase und eine schnelle, produktive Nutzung der Lösung. - Hoher Investitionsschutz

Das neutrale und generische Datenmodell macht Systemerweiterungen sehr einfach möglich und stellt sicher, dass sie auch nach Updates funktionieren. Gleichzeitig sorgt die kontinuierliche Pflege und Weiterentwicklung der Software für eine hohe Investitionssicherheit.

Ihr Ansprechpartner

Bernd Döbel

Open PDM– PLM-Systeme

integrieren und migrieren

OpenPDM ist die weltweit führende Lösung für die Synchronisation und Migration von PLM-Informationen in unterschiedlichen Anwendungs-Szenarien und Domänen - immer optimal angepasst an Ihre PLM Prozesse.

Das erste Release von OpenPDM wurde vor mehr als 20 Jahren bei unseren Kunden genutzt, um die beim Design von Automobilen entstehenden PDM Informationen automatisiert zwischen verschiedenen PDM Systemen zu synchronisieren. Heute verbindet OpenPDM alle PLM Domänen wie zum Beispiel Design, Produktionsplanung, Simulation, After Sales, Beschaffungswesen und weitere.

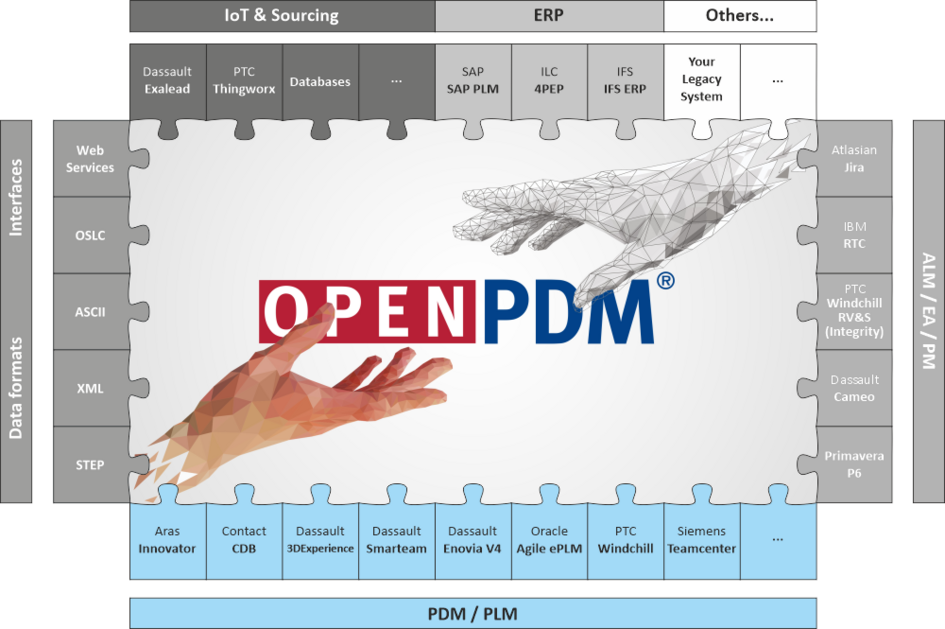

Welche Systeme kann OpenPDM anbinden?

Prinzipiell kann OpenPDM alle Systeme anbinden, die eine definierte Programmierschnittstelle zur Verfügung stellen. Auch wenn PROSTEP noch keinen Standard Konnektor zu ihrem System anbietet, so lässt sich eine Anbindung über das OpenPDM Konnektor Template schnell und einfach erstellen.

OpenPDM bietet fertige Standard Konnektoren unter anderem für folgende Systeme, weitere Systeme sind auf Anfrage verfügbar.

- Aras Corp. – Aras Innovator

- Arena/PTC– Arena PLM

- Atlassian – Jira

- Autodesk – Vault

- AVEVA – AVEVA Marine

- Cadmatic – CADMATIC

- Contact – Contact Elements / CDB

- Dassault Systèmes – 3DEXPERIENCE

- Dassault Systèmes – Cameo Cloud

- Dassault Systèmes – Exalead

- Dassault Systèmes – SmarTeam

- Diverse – GIT

- Hexagon – Nestix

- ILC Solutions – 4PEP PLM

- MongoDB – MongoDB

- Napa – Napa

- Oracle – Agile e6

- Oracle – Primavera P6

- PTC – Codebeamer

- PTC – Windchill

- PTC – Windchill RV&S (Integrity LM)

- PTC – Thingworx

- SAP – SAP PLM

- Siemens PLM – Teamcenter

- Siemens PLM – Polarion

- SSI – Ship Constructor

- Trimble – Nova

On-Premises oder in der Cloud?

OpenPDM ist “ready to run in the cloud”. Abhängig von Ihren Plänen, haben Sie die Wahl OpenPDM in Ihrer eigenen on-premises Umgebung zu betreiben oder Cloud Dienste zu nutzen. PROSTEP entwickelt und testet unter Nutzung der Cloud Dienste von AWS und AZURE. Auch unsere Kunden nutzen die Umgebungen von AWS und AZURE. Wenn Sie OpenPDM in der Cloud betreiben, so werden die OpenPDM Dienste als Docker Container ausgeliefert.

Product News

Ankündigung: Neuer Codebeamer Konnektor und Anbindung an Teamcenter über OSLC

MehrFrisch aus dem PROSTEP Labor möchten wir ihnen heute den neuen OpenPDM Codebeamer Konnektor vorstellen. Der neue Konnektor ist das erste technische…

Update für den PTC Windchill RV&S (zuvor Integrity) Konnektor

MehrWir haben unseren PTC Integrity Connector aktualisiert und unterstützen nun auch PTC Windchill RV&S

Neuer Connector: Dassault Systèmes CAMEO SYSTEMS MODELER

MehrWir haben unser Connector Portfolio um ein weiteres System aus dem Hause Dassault Systèmes erweitert: CAMEO SYSTEMS MODELER

OpenPDM verzahnt Entwicklung und Fertigung der neuen Pariser Metro

MehrBei der Entwicklung und Produktion der neuen Metro-Generation für die Pariser Verkehrsbetriebe arbeiteten Bombardier und Alstom schon vor ihrem…

Unser Netzwerk

Gemeinsam sind wir stärker. Als Kunde der PROSTEP AG profitieren Sie von unserem ausgedehnten Netzwerk an Technologie-, Vertriebs- und Servicepartnern sowie unseren Unternehmensbeteiligungen, die unser Lösungsangebot abrunden. Als Mitglied zahlreicher Organisationen haben wir den Finger am Puls der Technologie und beteiligen uns aktiv an wichtigen Forschungs- und Entwicklungsvorhaben, vor allem auf dem Gebiet der Standardisierung.

Technologiepartner

Synergien bündeln Wissen. Und Wissen schafft Lösungen.

Um unseren Kunden die bestmögliche Lösung anbieten zu können, pflegen wir seit jeher ein offenes Verhältnis zu allen Herstellern von IT-Systemen.

Wir unterhalten strategische Partnerschaften zu führenden CAx- und PLM-Anbietern.

Vertriebs- und Servicepartner

Unsere Vertriebspartner erweitern ihr Angebot mit Produkten und Dienstleistungen aus dem Hause PROSTEP. Diese Spezialisten beraten Unternehmen der unterschiedlichsten Branchen umfassend und kompetent.

Zu unseren Vertriebspartnern gehören Unternehmen weltweit.

Gemeinschaftsunternehmen

PROSTEP beteiligt sich an Gemeinschaftsunternehmen und bündelt damit Kompetenzen für seine Kunden oder bietet ihnen Zugang zu innovativen Technologien.

Mitgliedschaften

Die PROSTEP AG ist immer am Puls der Zeit und gestaltet neue Entwicklungen aktiv mit.

Dafür sind wir Mitglied in den folgenden Organisationen: